SolidViz

Project Goal

SolidViz is combination of 5 interactive 3D animation software developed as teaching aid for different material solidification phenomena.

Project Details

- SolidViz is developed as my B.S. final project at Isfahan University of Technology, Isfahan, Iran.

- Language used: Visual C++ 6.0 and OpenGL 1.2

- Source code is available upon request.

Introduction

SolidViz (Solidification Visualization package) includes following 5 interactive 3D animation softwares.

- Temperature effect on Denritic growth

- Crystallographic effects on Dendrite grwoth direction

- Growth morphology dependence on crystal structure

- Temperature effects on nucleation

- Spiral Growth

Dendrite Growth Packages

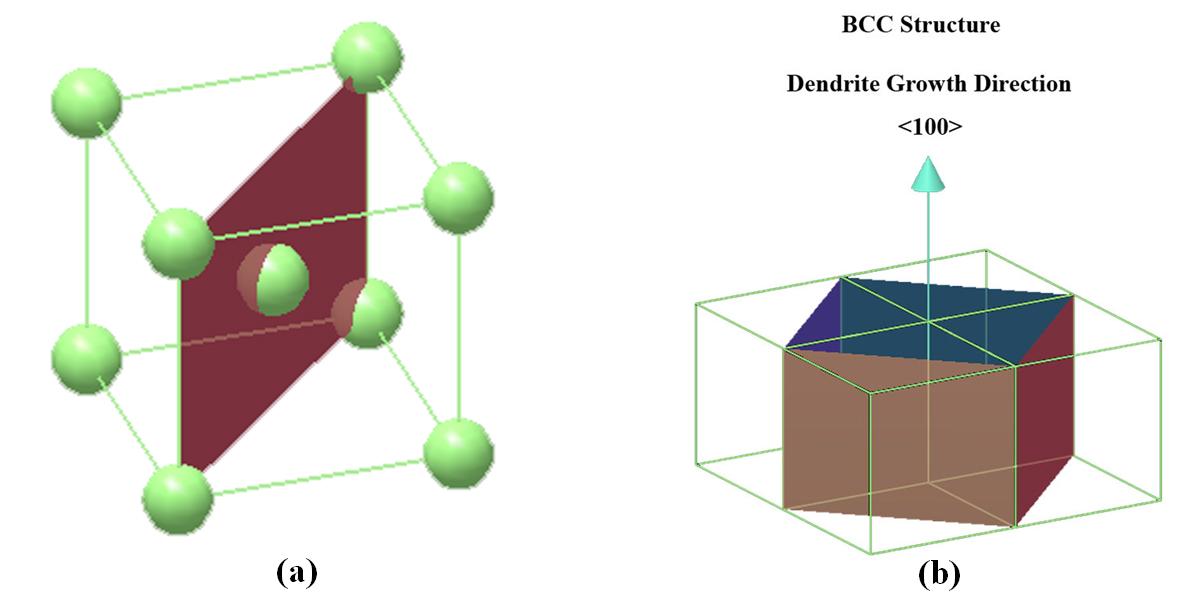

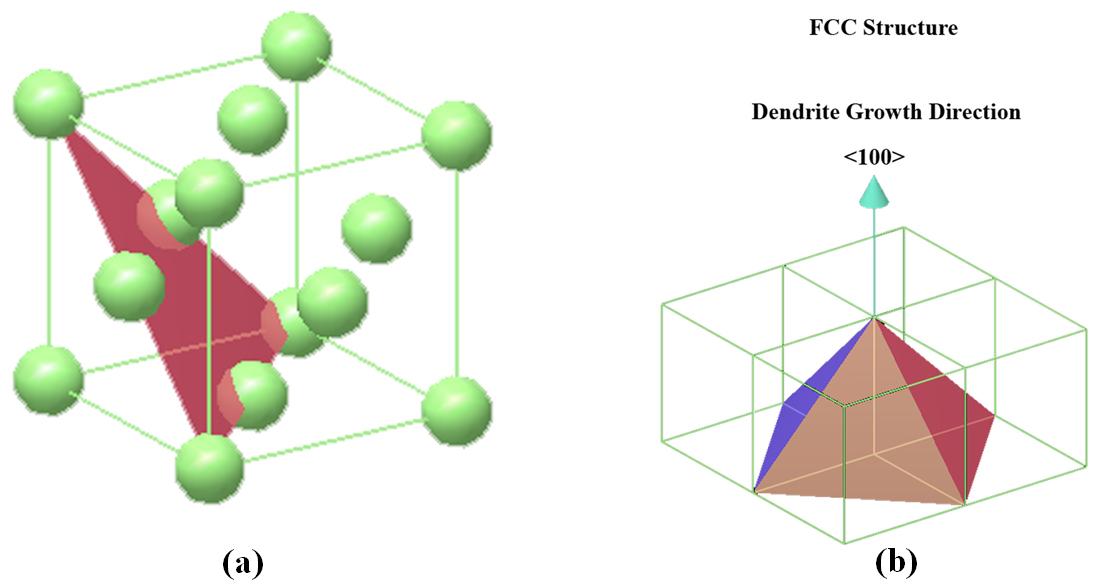

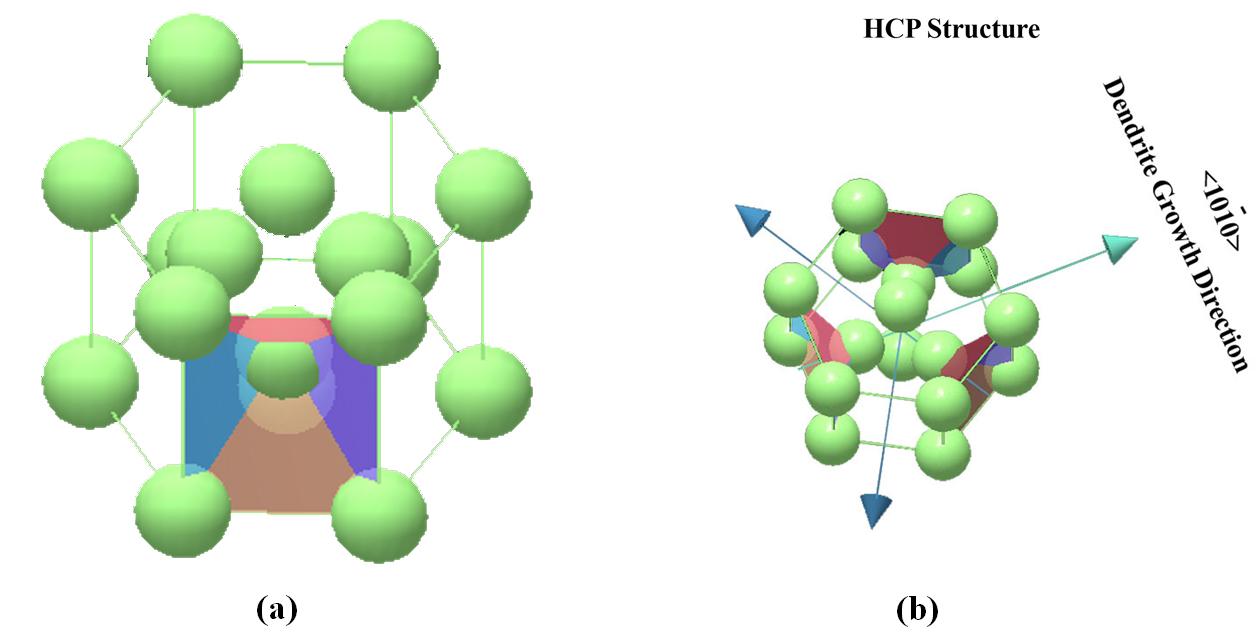

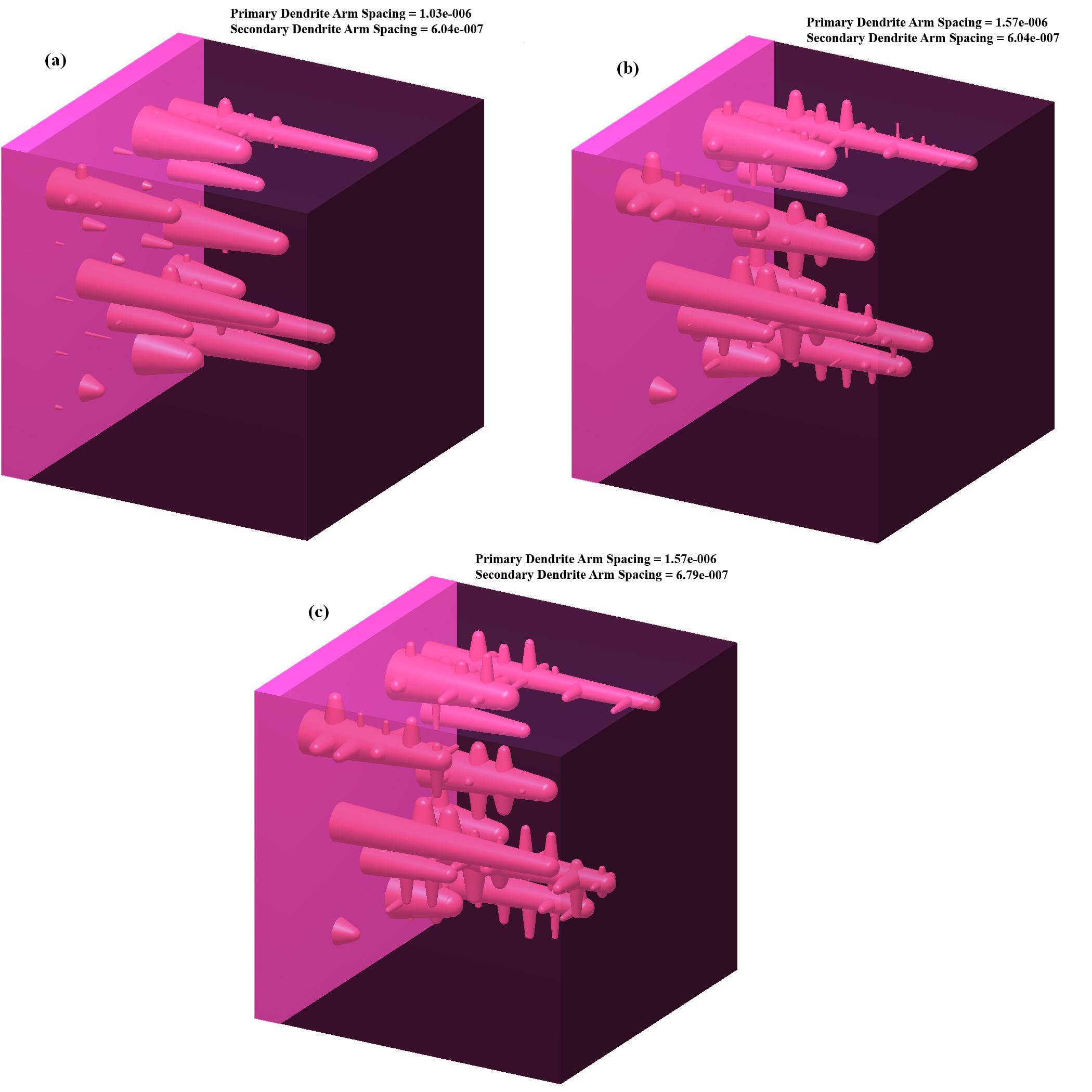

As the solid/liquid interface become unstable, dendrite arms tend to grow rapidly. Dendrite primary and secondary arms grow based on the growth direction which is dictated by material’s crystallographic structure.

Secondary dendrite arms have the parabolic shape. In the instability region of the solid/liquid interface, these arms tend to grow, while they may be eliminated by their neighbors. Therefore, only some are able to survive the coarsening process. These arms can grow only while their length is lower than half the length of primary dendrite arm, and depending on their size they can eliminate or be eliminated. The growth continues until the arm reaches the neighbor dendrite branches and then it stops. Thus, coarsening process would lead to fewer secondary dendrite arms with larger gaps between them.

In the dendrite growth direction software, three crystallographic systems considered, including BCC, FCC and HCP. For all structures high density planes are (110), (111) and (1012) family respectively. These planes create volumes that dictate growth direction in each structure.

For the dendrite coarsening software, a solid/liquid interface is visualized, so that the primary dendrite arms grow on this interface, while secondary dendrite arms grow on the primary ones. The geometry (radius and length) of each dendrite determined randomly to simulate experimental condition. In this case, small arms eliminate by the others after growing a bit, while coarser dendrites continue to grow and consume small ones. The software calculates primary and secondary arm spacing before and after coarsening as the animation progresses.

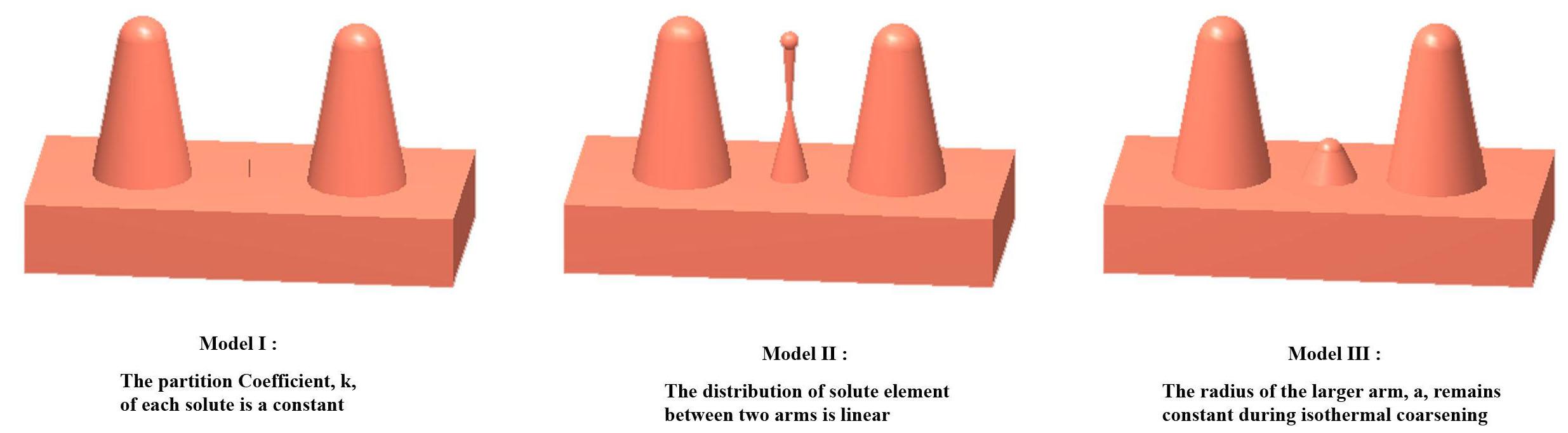

There are three different models that describe the coarsening process in different conditions. In the first model the partition coefficient (k) of each solute is a constant, therefore, the arm diminishes by becoming narrower in size. In the second model the distribution of solute element between two arms is linear, thus, the arm would diminish from its base. For the third model, the radius of the larger arm (a) remains constant during isothermal coarsening. In this model, the arm diminishes in length.